Services

Busbar Trunking System

Imagine a more efficient way to distribute electricity within a building. Busbar trunking systems offer exactly that. Instead of relying on multiple cables, busbars – flat copper or aluminum bars – conduct electricity within a metal enclosure. This offers several advantages:

-

Compact Design: Busbars are smaller than a bundle of cables, saving valuable space.

-

Faster Installation: Pre-fabricated sections and tap-off points for connection make installation quicker than traditional cable systems.

-

Flexibility: The system can be easily modified to accommodate future changes in power needs. New taps can be added to the existing trunking for additional equipment.

-

Safety: The enclosed design safeguards against accidental contact and protects from dust or debris.

-

Better Heat Dissipation: The metal enclosure efficiently dissipates heat generated during current transmission.

Busbar trunking is ideal for various applications. It’s often found in data centers, hospitals, and commercial buildings requiring a reliable and adaptable power distribution system.

ATE Panel

Since 2011, Advance Tech & Engineering (ATE) has been a leading force in Bangladesh’s electrical industry. One of our key offerings is locally manufactured electrical panels. These panels cater to various applications and boast several advantages:

-

Supporting Local Industry: By manufacturing panels locally, ATE contributes to the growth of Bangladesh’s manufacturing sector and potentially creates jobs within the community.

-

Reduced Lead Times: Local production allows for quicker response times compared to importing panels. This can be crucial for projects requiring faster turnaround.

-

Understanding Local Needs: ATE can potentially tailor panels to meet the specific electrical standards and regulations of Bangladesh, ensuring compliance with local codes.

-

Competitive Pricing: Local manufacturing may offer cost advantages compared to imported panels, making them a more budget-friendly option for some projects.

-

Customization Potential: ATE might be more receptive to customizing panels to meet specific client requirements when production is local.

Overall, Advance Tech & Engineering’s locally manufactured electrical panels offer a compelling option for projects that prioritize speed, budget, and supporting local industry. By carefully evaluating needs and ensuring proper certifications, these panels can be a reliable and cost-effective solution for various electrical applications in Bangladesh.

Type Tested Panel

In the world of electrical distribution, safety is paramount. Type-tested panels go a step beyond standard panels by undergoing rigorous testing to ensure they meet specific safety and performance standards. Here’s what makes them stand out:

-

Verified Performance: These panels are subjected to a battery of tests, including temperature rise, short-circuit resistance, and ingress protection. This ensures they can handle expected loads and environmental conditions without compromising safety.

-

Guaranteed Reliability: By passing these stringent tests, type-tested panels offer peace of mind. They are less likely to fail under operational stress, reducing downtime and maintenance costs.

-

Compliance with Standards: These panels adhere to international standards like IEC 61439, ensuring they meet global safety benchmarks. This is crucial for projects requiring regulatory approval.

-

Faster Project Approval: Since type-tested panels already demonstrate compliance, they can streamline the approval process for electrical installations.

-

Reduced Risk: The rigorous testing minimizes the risk of electrical accidents and fires, protecting personnel and equipment.

While type-tested panels offer significant benefits, they may come at a slightly higher cost compared to non-tested alternatives. However, the enhanced safety, reliability, and faster project timelines often outweigh the initial investment. They are ideal for critical applications like hospitals, data centers, and industrial facilities where safety and uninterrupted operation are essential.

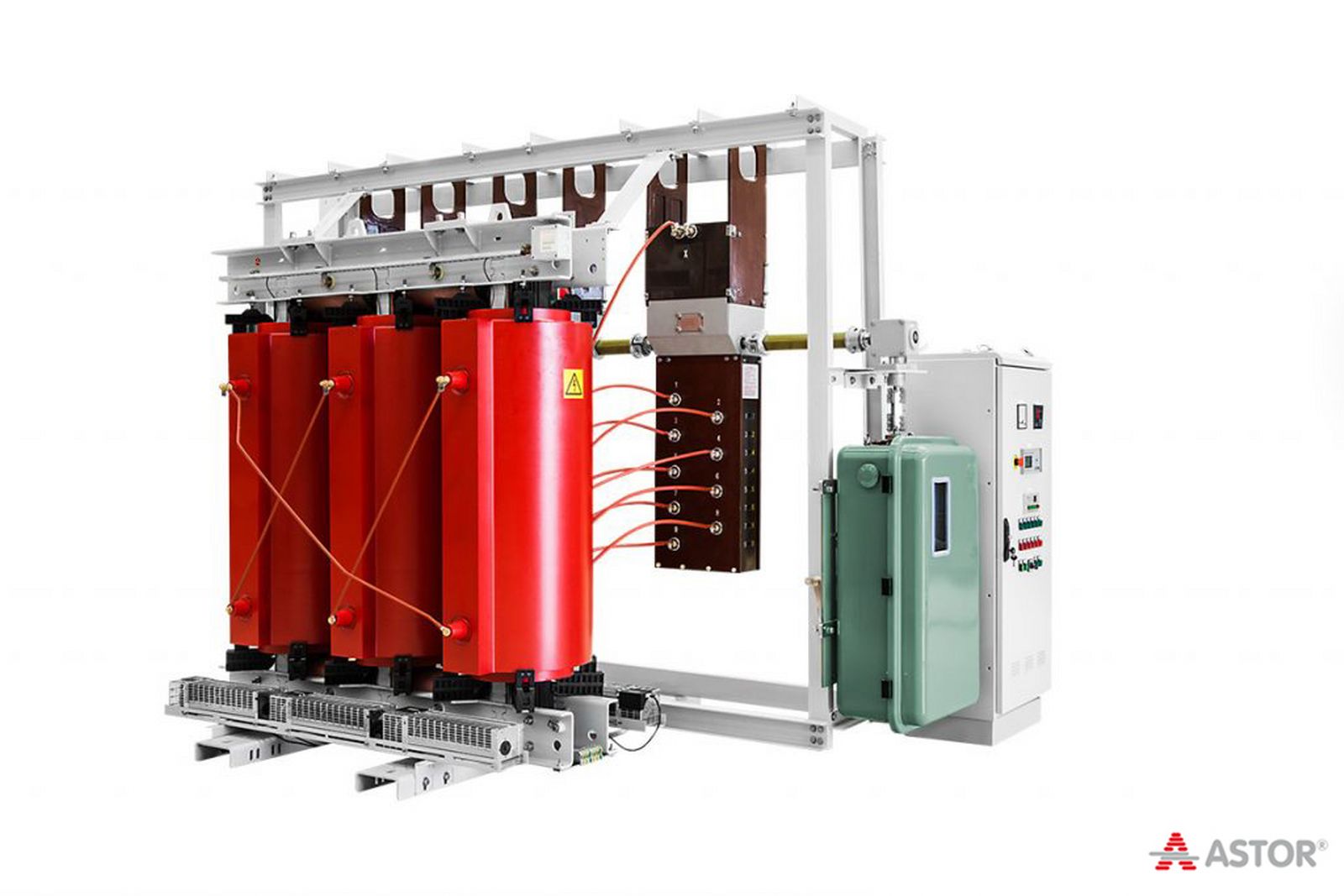

Dry Type Transformer

Unlike their liquid-filled counterparts, dry-type transformers offer a safe and eco-friendly solution for voltage conversion. Here’s what sets them apart:

Environmentally Friendly: Dry-type transformers eliminate the risk of oil leaks or spills, minimizing environmental impact. This makes them ideal for environmentally sensitive locations.

Fire Safety: Since they don’t use flammable liquids, dry-type transformers pose a significantly lower fire hazard. This is crucial for indoor applications like buildings and public spaces.

Clean Operation: The absence of liquids eliminates the need for containment measures and reduces maintenance requirements associated with oil leaks or disposal.

Compact Design: Dry-type transformers are often lighter and more compact than liquid-filled units, making them easier to install in space-constrained areas.

Versatility: They are available in various cooling configurations, including natural air ventilation or fan-assisted systems, allowing for adaptation to different environments.

However, dry-type transformers may have limitations. They typically have lower noise ratings compared to liquid-filled units and might be less efficient at handling very high power loads.

Overall, dry-type transformers provide a safe, sustainable, and space-saving option for voltage transformation in various applications, particularly those prioritizing environmental concerns and fire safety.